-

Extrusion Aluminum Profiles

-

Aluminum Pipes

-

Aluminum Rods

-

Aluminium Heatsink Profile

-

Automotive Aluminium Extrusions

-

Aluminum Structural Framing

-

Industrial Aluminium Profile

-

Architectural Aluminium Profiles

-

Aluminum Curtain Wall Profiles

-

Construction Aluminum Profiles

-

Aluminum Window Profiles

-

Aluminum Door Profiles

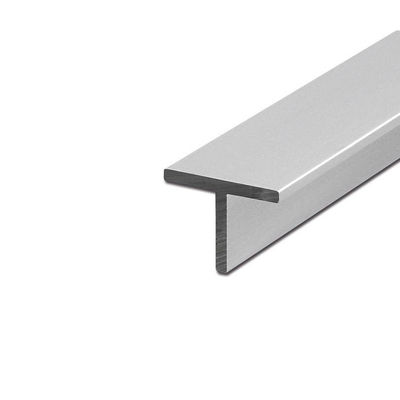

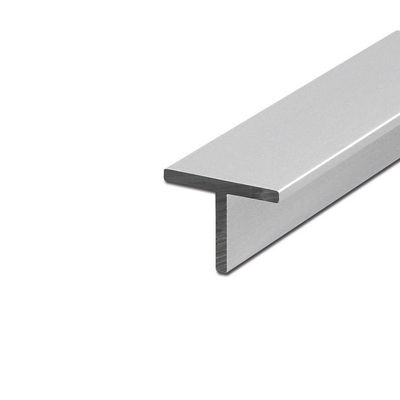

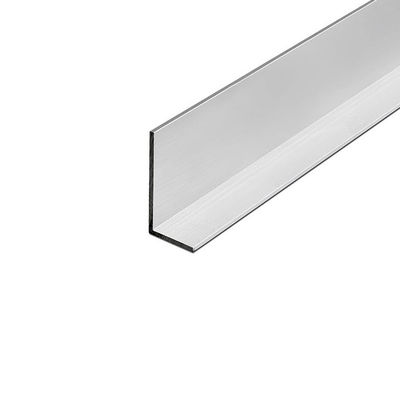

High Strength 6063 Aluminum Alloy Angle Profiles The Ideal Solution for Your Project

Contact me for free samples and coupons.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum | Color | Silver Or Black |

|---|---|---|---|

| Surface | Mill Finish Or Anodizing | Shape | Customized Shape |

| Application | Construction | Tolerance | According To Requests |

High Strength 6063 Aluminum Alloy Angle Profiles The Ideal Solution for Your Project

Discover our High Strength 6063 Aluminum Alloy Angle Profiles, the premium choice for crafting custom aluminum windows and doors. These profiles are forged from 6063 alloy, renowned for its excellent strength, workability, and corrosion resistance, making them perfect for architectural applications. Our advanced extrusion techniques ensure profiles with precise dimensions and a smooth finish, enhancing the durability and aesthetic appeal of your windows and doors. Ideal for both residential and commercial projects, these angle profiles offer a balance of lightweight design and robust performance. With the option for customization, our profiles can be tailored to meet the unique specifications of your project, ensuring a perfect fit and finish every time.

| Company Introduction | |

|

|

Founded in 2009, Sichuan Xinjiasheng Aluminum Company covers an expansive area of over 100,000 square meters. Renowned as a top-tier and proficient participant in the field, we excel at harmonizing research, conceptualization, fabrication, and commercialization of aluminum alloy architectural profiles and industrial aluminum profiles. Equipped with cutting-edge production machinery, our capabilities span aluminum alloy casting, mold crafting, aluminum extrusion, powder finishing, anodization, electrophoresis, and wood grain transference. Our product spectrum encompasses both standard and tailor-made aluminum profiles, enabling us to fashion profiles as per your furnished blueprints or prototypes. At Xinjiasheng, our ISO 9001:2015 certified facilities are a testament to our commitment, with a special emphasis on crafting end products from aluminum extrusions. Quality remains deeply embedded throughout every facet of our operations, commencing from inception through culmination. |

||

| Factory Area:100,000 ㎡ Employees: over 600 Extrusion Line:14 Annual production:50000 Tons Thousands of ready-to-use molds |

||

Specification

| Item | Extrusion Aluminum Profiles |

| Material | 6061 or 6063 |

| Temper | T6 or T5 |

| Characteristic | 1. Neat and beautiful fine lines on the surface. |

| 2. National standard aluminium billets are adopted. | |

| Application | building, Industry, Frame |

| Shape | Customization |

| Surface Treatment | Mill finished or Anodizing(Sand Blasting, Electrophoresis, Power coating or wooden transfercan be chosed) |

| Color | Silver, black, gold, Champange,Bronze, red, Blue; |

| We can customize the colors based on requests | |

| Delivery Time | Mold developing and sample conformation is 10-15 days, then production duration is 15-20 days after receipt of deposit from buyer. |

| Free Sample | Available |

Parts of Ready-to-use Molds:

![]()

Product Introduction

| Customized: We offer a flexible mold opening service tailored to your specific requirements. To initiate the process, all we need is a sample,a CAD drawing or the precise dimensions you desire for the mold. |

|

| Features: The combination of its light weight, strength, durability, corrosion resistance, and other versatile properties makes aluminum a highly versatile material used in a wide range of industries and applications. |

|

| Surface treatment--Anodizing: 1. Anodizing is an electrochemical process that convertsthe metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. 2. The thicker the anodic layer created, the greater thecorrosion resistance 3. Anodizing colours:Silver white, black, gold,platinumgrey, sandblasted siver white... |

Application

Aluminum profiles are used widely across industries, like construction (window frames, roofs), transportation (aircraft, cars), electronics (heat sinks, enclosures), furniture design (modern furniture, lighting), and industrial machinery (frames, supports).

Our advantages

1.Benefit from our extensive experience of more than 15 years in manufacturing aluminum profiles.

2.Our team consists of highly skilled professionals who are dedicated to delivering exceptional service and exceeding your expectations.3.Our products undergo stringent quality control processes, ensuring compliance with ISO9001, ISO14001, and IATF16949 standards.

4.Take advantage of our extensive selection of ready-to-use molds, providing you with ample choices.

5.Enjoy the convenience of our comprehensive one-stop service, encompassing design, mold production, extrusion, powder coating, anodizing, electrophoresis, wood grain transfer, packaging, and efficient delivery.

Workshop

![]()

Inspection equipment

![]()

![]()

FAQ

Are you a manufacturer or a trading company?

A: We are a reputable manufacturer with more than 15 years of experience in the industry.

Where is your factory located?

A: Our factory is situated in the Aluminum Silicon Industrial Zone, Xiuwen Town, Meishan City, Sichuan Province, China.

How do you provide quotations?

A: Quotations can be obtained by submitting a sample or drawing in CAD/STP/IGS format. Once we have assessed the material and surface treatment requirements, we will promptly generate a quote for your consideration.

What is the lead time for manufacturing new molds?

A: Typically, our lead time for developing new molds is 10-15 days.

Do you offer samples? If yes, is there a cost associated?

A: Yes, we provide samples free of charge. However, the customer is responsible for the freight charges.

What is your delivery time?

A: The mold development and sample confirmation process generally takes 12-15 days. Subsequently,the production duration is approximately 15-25 days after we receive the buyer's deposit.