-

Extrusion Aluminum Profiles

-

Aluminum Pipes

-

Aluminum Rods

-

Aluminium Heatsink Profile

-

Automotive Aluminium Extrusions

-

Aluminum Structural Framing

-

Industrial Aluminium Profile

-

Architectural Aluminium Profiles

-

Aluminum Curtain Wall Profiles

-

Construction Aluminum Profiles

-

Aluminum Window Profiles

-

Aluminum Door Profiles

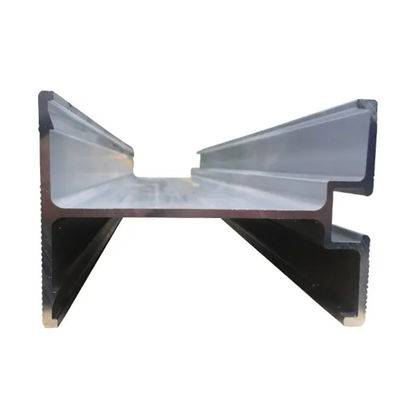

Machinery Equipment Industrial Aluminum Profile Oxidation Aluminum Structural Extrusions

Contact me for free samples and coupons.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminium 6063 T5 | Color | Silver |

|---|---|---|---|

| Surface Treatment | Mill Finish | Length | According To Requests |

| Application | Construction,industry | Grade | 6063 T5 Or 6061 T6 |

| High Light | Machinery Equipment industrial aluminum profile,Oxidation Aluminum Structural Extrusions,Machinery Equipment Aluminum Structural Extrusions |

||

Industrial Aluminium Extrusion Oxidation Profiled Machinery Equipment Construction

| Company Introduction | |

|

|

Established back in 2009, Sichuan Xinjiasheng Aluminum Company sprawls across a vast expanse spanning more than 100,000 square meters. Distinguished as frontrunners and adept specialists within the sector, we excel in unifying exploration, conception, production, and marketing of aluminum alloy architectural profiles and industrial aluminum profiles. Our state-of-the-art production apparatus envelops aluminum alloy casting, mold construction, aluminum extrusion, powder finishing, anodization, electrophoresis, and wood grain transference.Our product range caters to both standard aluminum profiles and customized profiles that can be extruded according to your specific drawings or samples. At Xinjiasheng, we take great pride in our ISO 9001:2015 certified facilities, meticulously established to produce your finished parts using aluminum extrusions. Quality is the cornerstone of every operation we undertake. |

||

| Factory Area:100,000 ㎡ Employees: over 600 Extrusion Line:14 Annual production:50000 Tons Thousands of ready-to-use molds |

||

Specification

| Item | Extrusion Aluminum Profiles |

| Material | 6061 or 6063 |

| Temper | T6 or T5 |

| Characteristic | 1. Neat and beautiful fine lines on the surface. |

| 2. National standard aluminium billets are adopted. | |

| Application | building, Industry, Frame |

| Shape | Customization |

| Surface Treatment | Mill finished or Anodizing(Sand Blasting, Electrophoresis, Power coating or wooden transfercan be chosed) |

| Color | Silver, black, gold, Champange,Bronze, red, Blue; |

| We can customize the colors based on requests | |

| Delivery Time | Mold developing and sample conformation is 10-15 days, then production duration is 15-20 days after receipt of deposit from buyer. |

| Free Sample | Available |

Product Introduction

| Customized: We offer a flexible mold opening service tailored to your specific requirements. To initiate the process, all we need is a sample,a CAD drawing or the precise dimensions you desire for the mold. |

|

| Features: The combination of its light weight, strength, durability, corrosion resistance, and other versatile properties makes aluminum a highly versatile material used in a wide range of industries and applications. |

|

| Surface treatment--Anodizing: 1. Anodizing is an electrochemical process that convertsthe metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. 2. The thicker the anodic layer created, the greater thecorrosion resistance 3. Anodizing colours:Silver white, black, gold,platinumgrey, sandblasted siver white... |

Application

Aluminum profiles are used widely across industries, like construction (window frames, roofs), transportation (aircraft, cars), electronics (heat sinks, enclosures), furniture design (modern furniture, lighting), and industrial machinery (frames, supports).

Our advantages

1.Our extrusion process yields high-quality mill finish aluminum profiles. Carefully monitored during production, our profiles are smooth and uniform. The extrusion dies are meticulously maintained to enhance surface smoothness.

2.Prior to anodizing and powder coating, we can also choose employ pre-treatment methods,sand-blasting. This offers matte surfaces for the raw extruded profiles and effectively removes surface dirt and oil stains.

3.Our products undergo stringent quality control processes, ensuring compliance with ISO9001, ISO14001, and IATF16949 standards.

4.Choose from an extensive range of readily available molds, offering versatility and options to suit your requirements.

5.Our comprehensive one-stop service covers all stages, from design and mold making to extrusion, powder coating, anodizing, electrophoresis, wood grain transfer, packaging, and timely delivery.

Workshop

![]()

Inspection equipment

![]()

![]()

FAQ

Material quality:

We use high-quality aluminum materials, including alloys such as 6063, 6061, 6082, and 6005, which comply with relevant quality standards and requirements.

Our aluminum alloy profiles have excellent strength and corrosion resistance, ensuring stability and durability during use.

Certification and standards:

Our aluminum alloy profiles comply with ISO 9001:2015 certification and relevant standards to ensure product quality and performance.

You can confidently choose our products as we adhere to high manufacturing standards and rigorous quality control processes.

Ordering and delivery:

Our ordering process is simple and convenient. You can contact our sales team for more details.

We offer flexible payment methods and reliable logistics arrangements to ensure timely delivery of orders to your location.

How do you provide quotations?

A: Quotations can be obtained by submitting a sample or drawing in CAD/STP/IGS format. Once we have assessed the material and surface treatment requirements, we will promptly generate a quote for your consideration.

What is the lead time for manufacturing new molds?

A: Our lead time for developing new molds is typically 7-15 days.

Do you offer samples? If yes, is there a cost associated?

A: Yes, we provide samples free of charge. However, the customer is responsible for the freight charges.