-

Extrusion Aluminum Profiles

-

Aluminum Pipes

-

Aluminum Rods

-

Aluminium Heatsink Profile

-

Automotive Aluminium Extrusions

-

Aluminum Structural Framing

-

Industrial Aluminium Profile

-

Architectural Aluminium Profiles

-

Aluminum Curtain Wall Profiles

-

Construction Aluminum Profiles

-

Aluminum Window Profiles

-

Aluminum Door Profiles

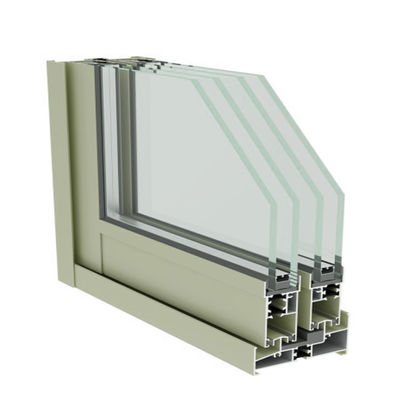

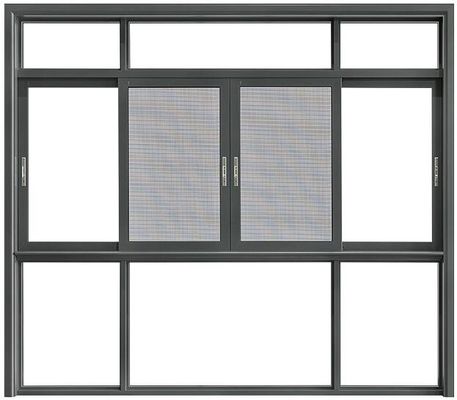

85 Series Aluminum Alloy Sliding Window Profiles 6063 T5 Aluminum Window Channel Extrusion

Contact me for free samples and coupons.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand Name | SGAS | Color | Green,white,grey,wooden Or Customized |

|---|---|---|---|

| Material | Aluminum Alloy | Grade | 6063 T5 Or Customized |

| Length | 3-6m | Surface Treatment | Powder Coating,wood Gain |

| Opening Mode | Sliding Window | ||

| High Light | 85 Series Sliding Window Profiles,6063 T5 Aluminum Window Channel Extrusion,85 Series Aluminum Window Channel Extrusion |

||

85 Series Aluminum Sliding Window Frame Profiles 6063 T5 Chinese Factory

Specification

| Item | Aluminum Window Profiles |

| Material | 6063 |

| Temper | T5 |

| Characteristic | 1. Neat and beautiful fine lines on the surface. |

| 2. National standard aluminium billets are adopted. | |

| Application | building, Industry, Frame |

| Shape | Customization |

| Surface Treatment | Power coating or wooden transfer(Mill finished, Anodized, Sand Blasting, Electrophoresis can be chosed |

| Color | Silver, black, gold, Champange,Bronze, red, Blue; |

| We can customize the colors based on requests | |

| Delivery Time | Mold developing and sample conformation is 12-15 days, then production duration is 15-25 days after receipt of deposit from buyer. |

| Free Sample | Available |

Surface Treatment

| Powder coating: 1.Advantages: High hardness of coating and strong adhesion.Varieties of colors are available 2.Powder coating colors: black,white,blue,coffee,customized |

||

|

Wood grain: capabilities of aluminum. |

||

| Anodizing: 1. Anodizing is an electrochemical process that convertsthe metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. 2. The thicker the anodic layer created, the greater thecorrosion resistance 3. Anodizing colours:Silver white, black, gold,platinumgrey, sandblasted siver white... |

||

| Electrophoresis: 1.Higher corrosion resistance,weather resistanceand alkali resistance than anodizing,with muchbrighter and smoother surface. 2.Electrophoresis colors:champagne,black,goldred copper... |

|

|

Colors(customized)

![]()

Product Superiority

Our factory possesses complete production lines, from casting aluminum rods to deep processing of aluminum profiles:

1.Our extrusion process yields high-quality mill finish aluminum profiles. Carefully monitored during production, our profiles are smooth and uniform. The extrusion dies are meticulously maintained to enhance surface smoothness.

2.Prior to anodizing and powder coating, we can also choose employ pre-treatment methods,sand-blasting. This offers matte surfaces for the raw extruded profiles and effectively removes surface dirt and oil stains.

3.The combination of these optimizations creates aluminum profiles that not only meet but exceed customer expectations, setting a new standard for quality and craftsmanship.

Our advantages

1.Benefit from our extensive experience of more than 15 years in manufacturing aluminum profiles.

2.Our team consists of highly skilled professionals who are dedicated to delivering exceptional service and exceeding your expectations.

3.Our commitment to quality is reflected in our strict adherence to ISO9001, ISO14001, and IATF16949 standards for product control.

4.Explore a diverse selection of ready-to-use molds that cater to various design requirements.

4.Choose from an extensive range of readily available molds, offering versatility and options to suit your requirements.

5.Our comprehensive one-stop service covers all stages, from design and mold making to extrusion, powder coating, anodizing, electrophoresis, wood grain transfer, packaging, and timely delivery.

| Company Introduction | ||

| Established in 2009, Sichuan Xinjiasheng Aluminum Company spans over 100,000 square meters. We are a reputable manufacturer, specializing in aluminum alloy architectural profiles and industrial aluminum profiles. Our expertise lies in seamlessly integrating research, design, production, and sales. Our well-equipped facilities include aluminum alloy casting, mold making, aluminum extrusion, powder coating, anodizing, electrophoresis, and wood grain transfer. Our product range caters to both standard aluminum profiles and customized profiles that can be extruded according to your specific drawings or samples. At Xinjiasheng, we take immense pride in our ISO 9001:2015 certified facilities, specifically designed to produce finished parts made from aluminum extrusions. Quality is ingrained in every aspect of our operations, from start to finish. | ||

| Factory Area:100,000 ㎡ Employees: over 600 Extrusion Line:14 Annual production:50000 Tons Thousands of ready-to-use molds |

||

Workshop

![]()

Inspection equipment

![]()

![]()

FAQ

Are you a manufacturer or a trading company?

A: We are an experienced manufacturer with over 15 years of expertise in the industry.

How do you provide quotations?

A: Quotations can be obtained by providing us with a sample or drawing in CAD/STP/IGS format. Once we have reviewed the material and surface treatment requirements, we will promptly generate a quote for you.

What is the lead time for manufacturing new molds?

A: Our typical lead time for developing new molds is 7-15 days.

Do you offer samples? If yes, is there a cost associated?

A: Yes, we provide samples free of charge. However, the freight charge needs to be paid by the customer.

What is your delivery time?

A: The mold development and sample confirmation process takes approximately 12-15 days. After the buyer's deposit is received, production duration is usually 15-25 days.